How AI Visual Inspection is Transforming Quality Control in Manufacturing

Introduction: The Era of Intelligent Manufacturing

In modern manufacturing, quality control is no longer about human inspectors manually scanning parts under bright lights. The rise of AI visual inspection—powered by computer vision and deep learning—is redefining how factories ensure precision, consistency, and reliability.

By integrating AI-based visual inspection systems, manufacturers are automating defect detection, accelerating production cycles, and achieving near-zero error rates. This technological leap is not just about efficiency—it’s about transforming quality control into an intelligent, data-driven process that continuously learns and improves.

What Is AI Visual Inspection?

AI visual inspection refers to the use of computer vision, machine learning, and neural networks to analyze visual data from cameras or sensors in real time. These systems are trained to identify even the smallest deviations—scratches, dents, misalignments, or inconsistencies—that traditional manual inspections might overlook.

Unlike conventional automation, which relies on fixed rules, AI-based visual inspection systems adapt and improve over time. As more visual data is processed, the system becomes smarter, detecting new defect patterns and optimizing quality thresholds autonomously.

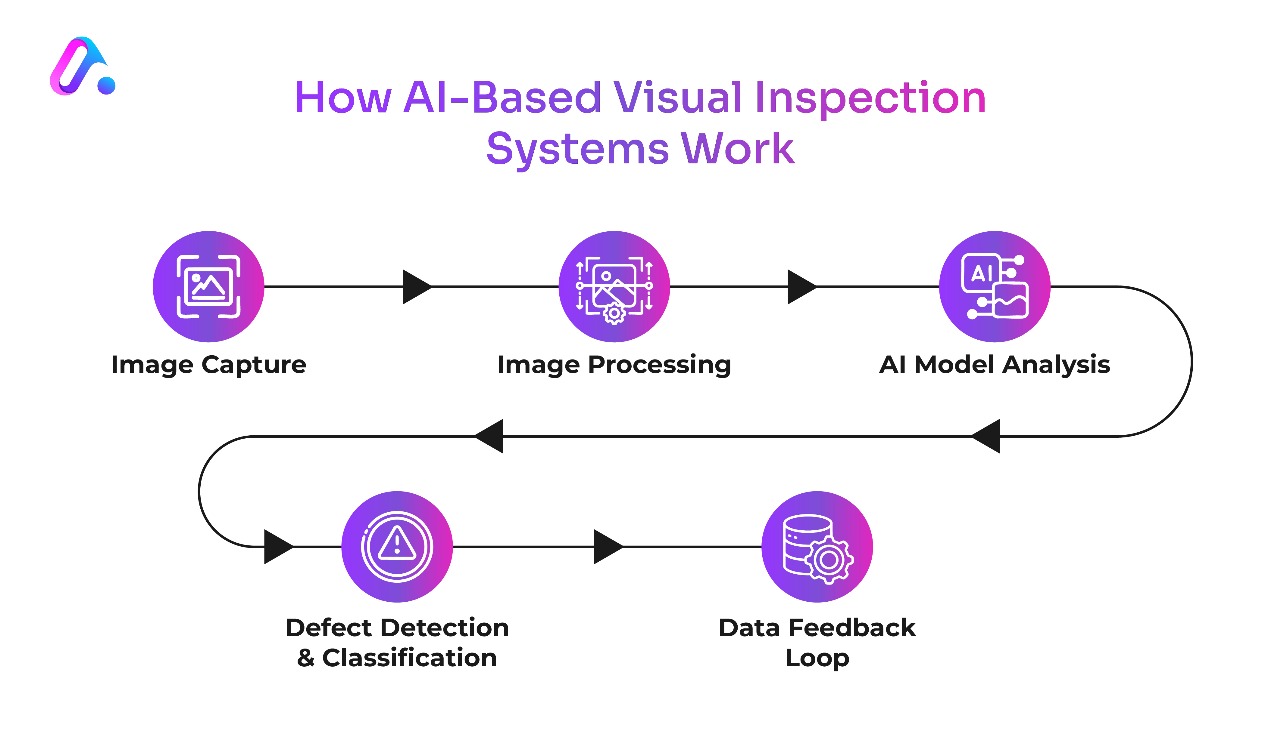

How AI-Based Visual Inspection Systems Work

- Image Capture: High-resolution cameras or 3D sensors capture product images or videos during production.

- Image Processing: The system preprocesses the visual data—normalizing lighting, removing noise, and segmenting regions of interest.

- AI Model Analysis: Deep learning algorithms, often CNNs (Convolutional Neural Networks), analyze patterns and compare them with pre-trained “good” product datasets.

- Defect Detection & Classification: The model identifies anomalies or defects, classifies their type and severity, and sends alerts in real-time.

- Data Feedback Loop: The more data the system receives, the better it becomes at detecting subtle defects—resulting in continuous improvement in quality control automation.

The Power of AI Visual Inspection in Quality Control Automation

1. Unmatched Accuracy and Consistency

AI eliminates human fatigue, subjectivity, and variability. Whether it’s the first product of the day or the thousandth, AI-based visual inspection systems deliver consistent quality judgments.

2. Real-Time Defect Detection

Instant alerts help operators act immediately, preventing defective parts from moving down the production line—saving time and material costs.

3. Scalability Across Production Lines

From electronics to automotive and aerospace industries, AI inspection models can be retrained and deployed across multiple production lines seamlessly.

4. Reduced Operational Costs

While initial implementation requires investment, the ROI is rapid—through lower scrap rates, reduced rework, and minimized quality-related downtime.

5. Data-Driven Decision Making

Every inspection generates valuable data. Manufacturers can analyze trends, identify recurring defect causes, and optimize upstream processes for long-term improvements.

Computer Vision in Manufacturing: A Paradigm Shift

Computer vision in manufacturing goes far beyond simple defect detection. It’s enabling factory-wide intelligence—connecting production lines, inspection stations, and quality analytics platforms.

AI-powered cameras now monitor:

- Assembly verification (checking correct component placement)

- Surface inspection (detecting scratches, cracks, or texture inconsistencies)

- Dimensional accuracy (ensuring geometric tolerances)

- Barcode and mark reading (for traceability and compliance)

The combination of computer vision and industrial AI inspection ensures that every product leaving the factory meets exacting quality standards.

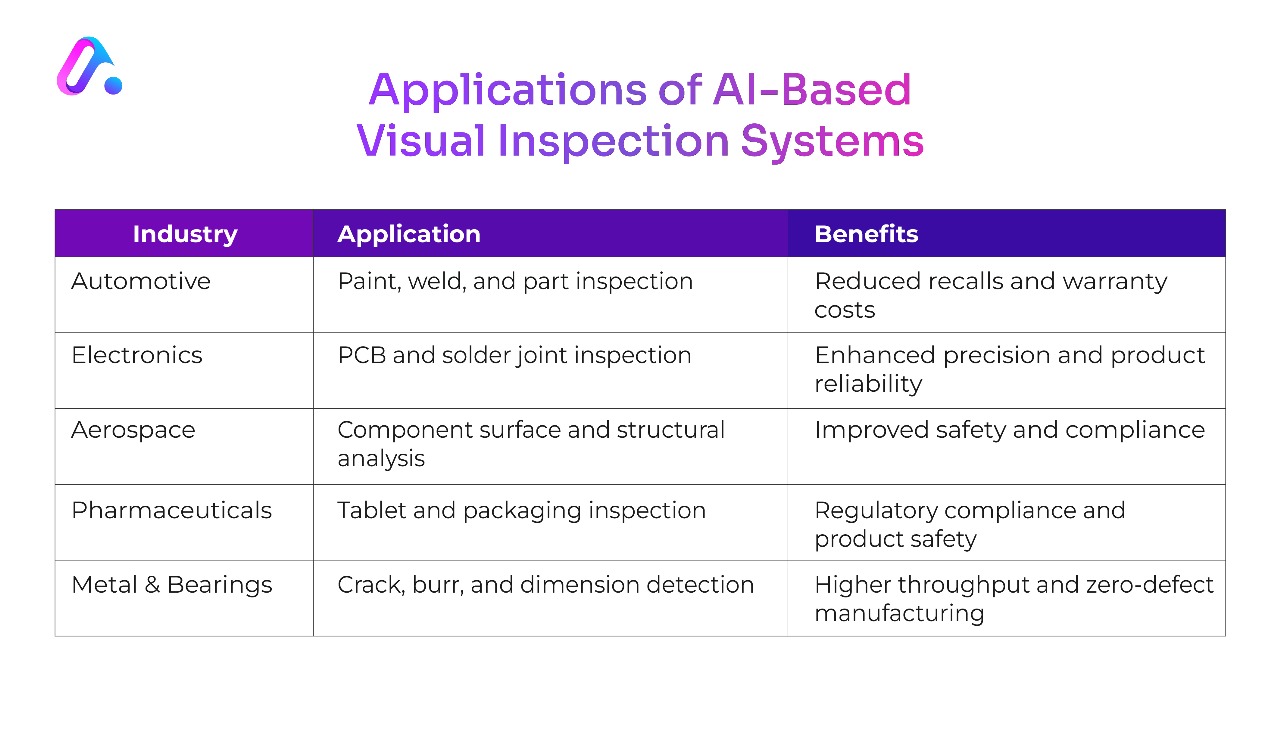

Applications of AI-Based Visual Inspection Systems

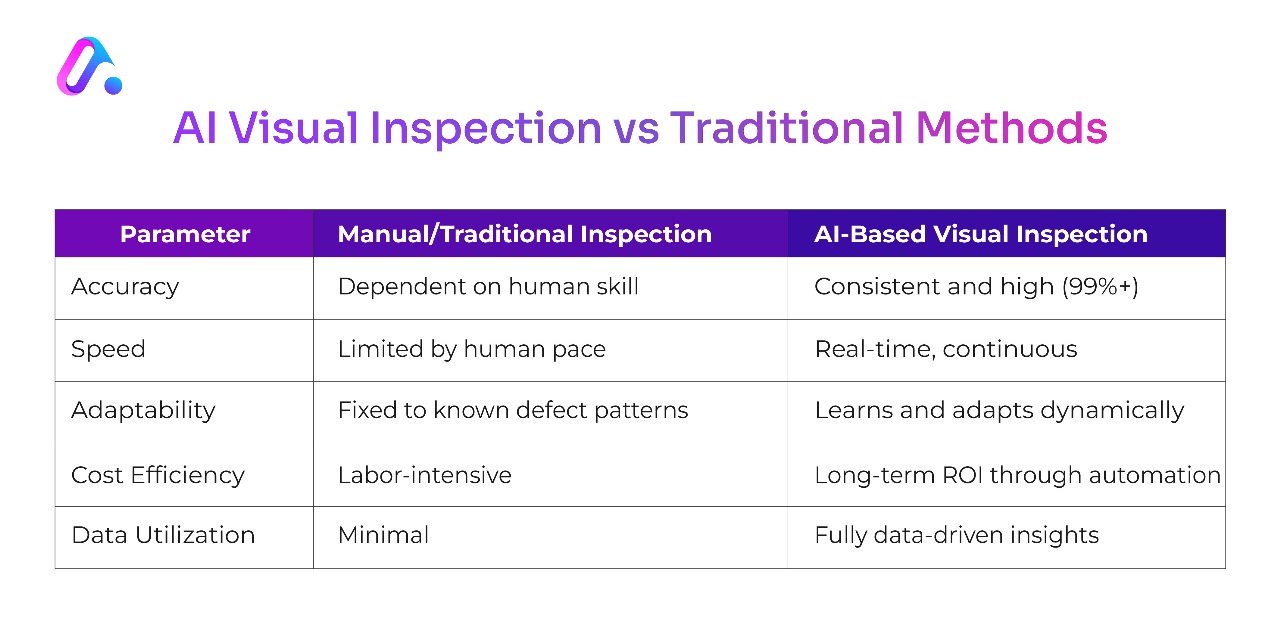

AI Visual Inspection vs Traditional Methods

The Future of Industrial AI Inspection

The next generation of AI visual inspection systems is integrating:

- Edge AI for real-time decision-making directly on production lines

- IoT connectivity for seamless data exchange across factory systems

- Generative AI for simulating and predicting unseen defect patterns

- Predictive quality analytics that prevent defects before they occur

This convergence is setting the stage for autonomous factories, where automated quality checks are continuous, adaptive, and self-correcting.

Conclusion: The Path to Zero-Defect Manufacturing

AI visual inspection is not just a tool—it’s a transformation catalyst for global manufacturing. By combining computer vision, machine learning, and quality control automation, industries are achieving what was once impossible: zero-defect production, optimized operations, and superior product quality.

As the world moves towards Industry 5.0, where human expertise collaborates with intelligent machines, AI-based visual inspection systems will play a central role in building factories of the future—smart, sustainable, and precise.